A blend of art and science – is what you can call ‘wood polishing.’ The wood polish acts as an envelope to embellish and secure the wood by incorporating fashion and durability characteristics. The polyester polish finish will accentuate the elegance of the wood or cover up the imperfections of the wood substrate bringing out the wood’s natural beauty. The finish can be semi-opaque, giving a driftwood look and feel to the piece, or can be applied to paint the whole piece, indicating very little or no wood grain concept.

For producers of wood furniture, kitchens, office furniture, and multipurpose cabinets, wood finishing suppliers formulate, produce and service wood polishing products. Their technical knowledge and service skills help educate the producer about applying and managing the wood finish. In the manufacturing of furniture or cabinets, wood polishing is one of the last processes. With regard to their look and feel, the wood polish emphasizes the mission of the furniture and cabinets. It activates the emotional reactions of customers to the senses of sight and feeling. The retail customer notices that the item is either attractive or unattractive. The next move is to feel and rub the finish. If the piece looks and feels fine, it produces a “take me home” signal. A nice finish on furniture or cabinets may do a lot to compensate for a mediocre design. A poor finish, by comparison, would distract from well-designed furniture and cabinets.

Polyester Coating – Best Wood finish

A wood polish may accentuate a geographic region or historical period. Some typically built, furniture and cabinets finished in a dark pine wood polish represent a spacious look. In all forests, lighter finishes produce a more ‘spacious,’ upscale look, with a country flair. For those wishing to use the highest possible, solid wood coating and minimize or remove emissions, polyester is the best wood finish. The proportion of solids can be as high as 100% by weight and 100% by volume. Polyesters are exceptionally high in solids and have limited use because they lack versatility in applying ornate furniture and cabinets. They are hard to patch as well. In a flat-line, UV-curing roll-coat atmosphere device or a two-component spray procedure for a flat-line finishing application, polyesters are best added.

In Europe, wood finishes were created from polyester/urethane “wet look.” They also gained prominence in India in 2010. As the Indian furniture industry faced substantial competition from abroad, the Indian industry became more market-driven and was forced to embrace the “European Wet Look” at least partially.

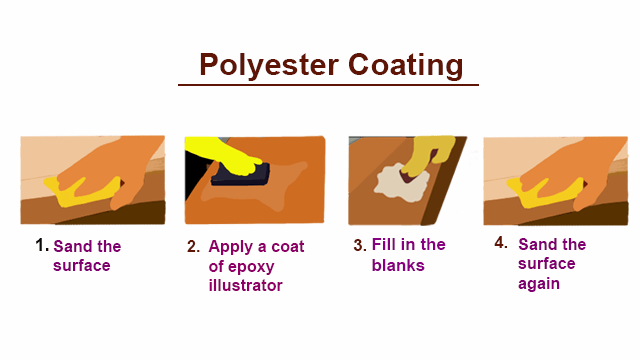

Polyester Coating Process

Step 1 – Sand the surface

This is a preparatory and one of the most overlooked steps. Yet, the importance of this step cannot be skipped. The initial stages determine the final result of the finish. You need to use 220 grit paper to remove any marks, stray materials, or any leftover adhesives. This process will ensure that the surface is clean and smoother for the next steps. Don’t forget to wipe off dust particles at the end of the sanding.

Step 2 – Apply a coat of epoxy illustrator.

Now we start with the process of bringing out the sheen of the veneer. In this step, the critical point is to mix the epoxy with its’ hardener in portions of a 1:1 ratio. Epoxy is a potent mixture that helps in exposing the colour of the veneer. You can choose to apply as many solutions as you want, depending on how dark you want the shade to be.

Step 3 – Fill the deformed or uneven areas.

Natural wood has deformities, and it is usual to have holes and dents on the surface. The same can be said about the colour of those holes. Usually, they are several shades darker than the rest of the surface. It would be best if you filled those dents and holes with wood fillers matching the wood’s colour. If the holes are greater than one sq. mm, fill them with polyester putty to reach even height.

Step 4 – Sand the surface again.

After carefully taking care of the deformities, you will have to sand the surface again. You might feel that this step can be skip upon. However, sanding is paramount to achieving an even and smoother output. Sand the surface with 220 grit sandpaper and remove any dust particles from the surface.

Step 5 – Apply another layer of epoxy illustrator.

Apply another layer of epoxy coating. You can follow the same guidelines as listed in step 2.

Step 6 – Apply polyester coating.

Now is the time to start with the polyester coating process. A room temperature reading above 20 degrees Celsius is a prerequisite before polyester application. You will have to apply multiply coats of polyester on the surface to the tune of 10-12 coatings. You will have to exhibit patience and allow a rest time of 3 to 5 minutes between layers. It would help if you gave the coating enough time to rest on the surface before applying again.

Step 7 – Post verification steps.

Any quality product always goes through a final quality check. To be confident in your polyester coating process, verify that the thickness has increased by 1.5mm to 2mm or more. The increase in thickness suggests that you have followed all the steps to the spec.

Buffing is a quintessential step.

After the application of polyester, buffing is mandatory to get the needed gloss from the surface. A good suggestion is to allow at least 12 hours of rest time before starting with the buffing process. A brief on the buffing process is below.

Preparation

- Sand the surface with 400 grit dry paper. The purpose of this step is to remove spray marks.

- Sand the surface with 600 grit dry paper to remove stains made by 400 grit dry paper.

- Sand the surface with 1000 emery paper, then 1500 emery paper, and then finally with 2000 emery paper.

Buffing process

– To achieve the best results, you need the best tooling. Use a good quality buffing machine.

– Grit paper and emery paper do leave marks on the surface. Use supercut liquid rubbing with wool pad twice on the surface. This first step is to remove any marks left by the preparatory steps listed before.

– To step up the surface’s shiny gloss, you need to use easy polish with lamb’s wool pad once. This step will bring about the glossiest finish on the surface.

– Finally, to make the gloss sustainable, you need to apply FPTE polish with a foam pad or cotton. This will create a protective layer on the surface to save it from water, marks, or other stains.

The Future of Polyester Coating

The changeover to a high-technology polyester and polyurethane polish became a challenging and expensive adventure for manufacturers – previously using mainly nitrocellulose-based products. They are implemented scientifically, with strict controls of execution.

For many skilled wood polishers who were used to working with more tolerant and easy-to-use nitrocellulose products, the high-tech, clean-room polyester/urethane process was a “culture shock.” Finishing errors dependent on nitrocellulose can be washed away and quickly corrected. For polyester and urethane wood finishes, which are very difficult to fix, this is not the case. Method errors allowed the manufacturer to start over. Before the finish dried, the edges of tables and chairs were “bumped,” causing significant quality concerns and extra expenses.

Home Glazer is a leading polyester polish services in Delhi NCR. Our overall vision is to beautify properties and ultimately be a value provider to their clients. We have an illustrious background in providing Wood Polishing Services in the Delhi region. We carry over our expertise in wood coating. You will find our name on Google prominently if you are looking for the Best polyester polish services.

Home Glazer is a trusted wood polish services provider with outstanding results in PU Paint, PU Polish, Polyester polish and other High-end wood polish categories. We approach our work with a holistic view and resolve customer doubts around the process end-to-end. Thus, we strive to deliver clean and cheerful results and that too at nominal cost-effective rates. We assure for outstanding result for your wood polish requirement If you hire us.

Relevant Posts

- What is DUCO Paint? DUCO Paint Coating Service Process | Duco paintDuco paint is a premium quality air drying paint, which is ideal for all types of metal and wood surfaces. It dries off faster and has excellent colour retention, therefore, preferred by house painters. Its high solid content, excellent water resistance, self-leveling… Read more: What is DUCO Paint? DUCO Paint Coating Service Process | Duco paint

- What are The Different Types of Wood Polish and Finishes for Wood?Though paint and varnish are important for maximizing the durability of wooden items, yet it is vital to finish their decoration with a perfect wood polish which not only protects the coat but also provides it with a long-lasting glossy texture. Major… Read more: What are The Different Types of Wood Polish and Finishes for Wood?

- Useful Information of Sirca PU Paint & PU Polish – Your Italian AutographSirca PU: Nature-inspired high-quality PU coatings – Sirca, a prominent market participant in the sector of Paints & PU Coatings, has been welcoming itself into people’s homes, standing strong to this concept. It is thought that Italian decor ideas would carve out… Read more: Useful Information of Sirca PU Paint & PU Polish – Your Italian Autograph

- Useful Information of ICA PU paints & PU Polish – Italian Wood FinishICA PU – In the premium wood coating segment, ICA brings to you a world-class range of wood coating products through their joint venture. ICA Group is situated in Civitanova Marche, a seaside town in central Italy, and is one of the… Read more: Useful Information of ICA PU paints & PU Polish – Italian Wood Finish

- Tips from Home Glazer for Maintenance of DUCO Paint FurnitureDUCO Paint is popular for its exceptional quality, durability, and premium finish. These qualities of DUCO paints make it a good choice for furniture, doors, and other wooden accessories. Everyone wants that their DUCO paint surfaces to maintain its classy condition and… Read more: Tips from Home Glazer for Maintenance of DUCO Paint Furniture

- Steps to Restore Wooden Furniture | Furniture Repairing ProcessWe all have that one piece of furniture that means a lot to us. It may be an heirloom from a family member or a special piece that we’ve bought with our own money. Regardless of its sentimental value, over time, all… Read more: Steps to Restore Wooden Furniture | Furniture Repairing Process

- Similarities & Differences between Duco Paint and PU PaintEveryone wants to give a luxurious texture to their wooden furniture and to protect them from scratches and stains. DUCO paint and PU paints are used for the same purpose. They have high resistance against heat, excellent hardness, in-depth clarity, and corrosion… Read more: Similarities & Differences between Duco Paint and PU Paint

- Reasons to Choose PU Paint Over DUCO PaintEveryone wants their furniture to have a beautiful feel to it while still being protected from scratches and stains. DUCO paint and PU paint fulfill the same function. They are heat resistant, durable, have deep transparency, and are corrosion resistant. They also… Read more: Reasons to Choose PU Paint Over DUCO Paint